Customization Trends

The world of customized merchandise is incredibly vast, and the segment is evolving fast thanks to advancements in technology such as 3-D printing, networked production and high-speed data transmission, enabling mass customization like never before.

After all, focusing operations on product development diversifies the range of merchandise in order to keep current customers engaged with your brand, always coming back, and looking for what’s new.

Ashley Miller, sales representative for Gib Carson, said

that technology advances in customized product has

come a long way.

“What used to be a few hundred-piece minimum is now allowing small business retailers to cash in on unique, custom products in as little as 12/each minimums for products,” she said. “In the last two years, with this technology, I’ve had successful retailers create custom products that are giving the consumer the unique find and the retailer low risk due to lower minimums—it’s a win-win!”

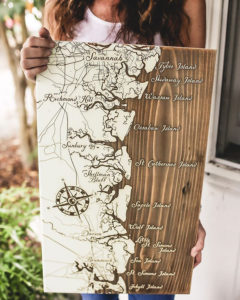

Ryan Lanzel, executive vice president and creative director for Fire & Pine, based in Ridgeland, South Carolina, noted for companies like his, which manufacture products in-house from scratch, many have utilized laser engravers.

“The technology behind laser engravers has become much more user-friendly over the years, allowing just about anybody with an idea the means to create something new and useful with limited experience and training,” he explained. “The technology has also become more affordable, and with more competition between manufacturers, each new machine is more user-friendly than the last.”

Fire & Pine uses a number of different technologies in its production but laser engravers, Lanzel noted, is one of the most important, as it has the ability to cut or engrave on a wide variety of substrates from wood, acrylic, glass, slate, metals, and more.

“Whether you simply want to add an artistic spin onto an existing item, or create a completely new piece of merchandise from scratch, the laser engraver is an incredible tool to help accomplish this,” he said. “We use our fleet of lasers to not only create the artwork we sell, but to also innovate displays, jigs and problem solve other issues that may arise across our manufacturing floor.”

Retailers can purchase user-friendly tabletop engravers with indoor exhaust extractors to utilize a smaller inventory of blank customizable items, and create unique work on the spot for customers in their shop.

So, with the right tools, a retailer doesn’t need to purchase and inventory 1,000 keychains with every first name on them, as they can simply rotate a much smaller inventory of blank keychains and create only what is in demand.

Tamara L. Moran, president of Yarmouth, Maine-based Town Pride, a curated collection of custom goods sold at wholesale to independent gift shops, noted with new technologies comes greater creativity and the opportunity to customize a wider selection of products in a shorter time frame and in lower quantities.

“We’re seeing a lot of experimenting with decorating on different materials and fibers,” she shared. “We are also developing multi-faceted designs using more than one type of decorating on a singular piece, adding texture, depth and interest.”

Kern Stevenson, director of business development for Leewood, Kansasbased DEMDACO, explained how automation is reducing the back and forth with customized product.

“The rendering stimulates purchasers with new merchandising ideas, helping to consultatively guide the purchasing decision, saving them decision-making time,” he said. “Our initial exploration has involved laser engraving and printing because it allows greater flexibility with a variety of our existing product types.”

MORE PRODUCT EQUALS MORE CUSTOMERS

Not only does customization invite current customers to keep your brand at the forefront of their minds, it also opens doors to new potential clients who may not be the market for your current offerings.

“We have very limited opportunity to capture the attention of customers, so by providing a wider variety of goods, we allow more face time with the customer to browse and understand our brand,” Lanzel shared.

Moran is most excited about digital—especially DTF—as well as 3D embroidery and newer sublimation techniques, which she said brings a larger cross-section of the public into the store.

“It’s our designs or artwork that win over our customers, coupled with the newest technologies and quality goods,” she noted, pointing out the top categories at Town Pride are knits, drink ware and home goods. “Apparel is great but a whole collection is better. When you can tell a local love or custom story in your shop with coordinating products, it builds the sale, adds to the customers’ experience and will make your store the go-to for all things custom.”

Moran loves embroidery for the depth of the design and the flexibility to offer multicolor options — especially on apparel and home goods. She also feels dye sublimation is quick, easy and endless in possibilities.

“You can sublimate on apparel, drink ware, jewelry, signs, pillows… the list goes on and on and we love the vibrancy of the colors you get with sublimation,” she said.

One technology Miller sees becoming more popular is UV Printing, which she noted creates a stunning, vibrant color on products, giving it a high-quality feel that’s now available to retailers.

NEW PRODUCTS EMERGING

The advent of new technology has also allowed some products to be customized that may not have been offered in the past. For instance, Lanzel noted there have been some innovations with substrates over the years that make manufacturing, customization and ease-of-use much more user-friendly.

“Laserable Leatherette is a product that offers the look and feel of genuine leather at a fraction of the price and also provides the ability to choose not only the surface aesthetics but also the color of the engraving as well,” he said.

Some of the newer products Town Pride is working with include knit sweaters, candles, bath and body items and printed food products. Another company that has been innovating products is Epicurean, a manufacturer of customizable dishwasher safe, knife friendly, heat resistant, and Made in the USA cutting boards and kitchen utensils. They offer a fantastic eco-friendly option over a traditional bamboo or plastic cutting board.

“Apparel is still a top-selling product in the customer category, but the emerging trend and one to pay attention to has been in home décor, drink ware, barware and garden,” Miller said. “The consumer wants something more tangible to commentate their hometown, special occasion or road trip. The technology now allows wholesale suppliers to customize these home products whereas before it wasn’t possible.”

Having more options allows for a more enticing visual store. After all, Stevenson noted, expanded displays make a stronger in-store statement and engage a broader cross section of consumers.

NAMEDROP TRENDS

By utilizing a few simple universal designs such as a nature scene, hiker silhouette, canoe, etc. with the ability to namedrop gives the customer the feeling of a one of a kind custom item, shared Lanzel.

“Small, simple pieces such as stickers and patches at an affordable

price point make for the perfect grab-and-go add on item,” he said. Simple clean designs with pops of color and licensed artwork designs are also trending, and Stevenson added that relevant regional sayings that localize are becoming more creative.

One of the most exciting, bestselling custom or namedrop product line-ups Miller has seen successful with retailers is with Carson Home Accents, which offers an entire catalog featuring hundreds of products that are just namedrop.

“Most popular include hometowns, zip codes and area codes,” she said. “Over the last two years, they have expanded into low-minimum name drop categories to accommodate a lot of growing trends projected through 2026.”

And with technology continuing to advance, and innovation at an all-time high, the customization segment is expected to only gain more prominence in the years to come.

This article originally appeared in Waterfront Living 2022.